Multiple design options in our compression limiters. Vogelsang offers an extensive line of cost saving compression limiters.

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

4 ENGLISH Keep dirt and foreign matter out of the hydraulic system of the tool as this will cause the tool to malfunction.

. Such features as the specific plastic filler mold design wall thickness and stress concentrations all impact the durability of the plastic. Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies. PIN Limiter Diodes for Radio Transceiver Protection The radio transceiver is a device that can send and receive information over the same medium.

SPIROLs Application Engineers have vast experience in Compression Limiter design production techniques and installation methods to maximize the benefits within the assembly. SPIROLs Series CL200 CL220 and CL350 split seam Compression Limiters are produced with flexible diameters to accommodate wide hole tolerances. 1 Design Guide Threaded Inserts For Plastics a ten point guide.

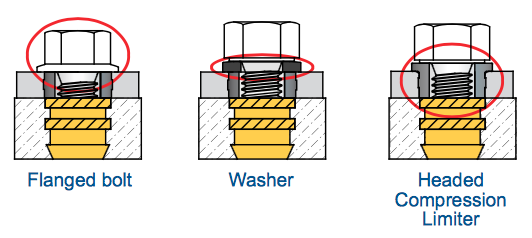

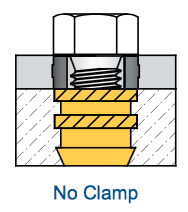

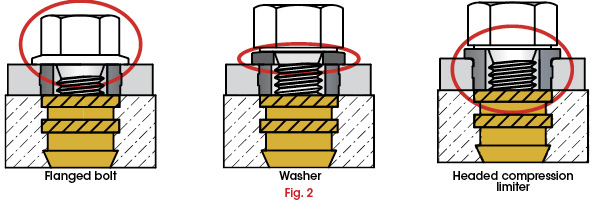

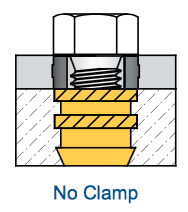

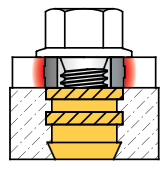

Compression Limiters are designed to protect the plastic components of an assembly from the compressive loads generated by tightening bolts. They are designed with various knurl configurations and undercuts in order to meet the strength requirements of the specific application. SI Brand Compression Limiters.

Design guidelines for Compression Limiters to avoid the risk of exceeding the elastic limit of the plastic component. Included are the specifications for their standard split seam molded-in and solid wall designs as well as their brand new oval series. This knowledge obtained both from theory and practical experience is tested and expanded upon continuously through actual applications.

Guidance and advice for those involved in the design of plastic products requiring threaded inserts. Compression Limiters are plain hole metal inserts designed for use in plastic mould components. By pushing the gain up while keeping a ceiling on the output an increase in loudness can be achieved.

The Series CL400 Oval Press-In Compression Limiter accommodates up to 225mm extra clearance on one axis providing additional flexibility over round Limiters for centerline and stack-up tolerancing. Compression Limiters are designed to protect the plastic components of an assembly from the compressive loads generated by tightening bolts. DIN EN 16983 formerly DIN 2093 Stainless Steel.

A limiter can protect these components. This application note describes in detail the circuitry for two basic com-pressorlimiter designs using these devices. Care should be taken to ensure that.

The integrity of the plastic is not compromised by the load that is applied. 1 COMPRESSION LIMITERS x 2 2 - 1 2 A C B L. Compression limiters are non-threaded bushings made of various materials.

As a general guideline 2-3 compression of thermoplastic materi. Threaded Inserts for Plastics. The innovative Series CL500 are roll formed insert.

Hole Design Although the split seam. Addressing these design issues prior to requesting quotes will insure you are using the most cost effective Limiter for your application. The second design adds a soft-knee threshold.

The compression limiter strengthens the plastic and withstands the compressive force that is applied when a mating screw is tightened. Dodge Applications Engineers are available and ready to assist you in the design and development of the optimum bushing for. There are too many variables involved to make a specific calculation.

Anti-Creep Spacers Compression Limiters. The load causes compression which can lead to cracking and creep due to tightening torque. Headed Compression Limiters are only available as solid components because of the tolerances required for proper Compression Limiter operation.

2 SPIROLs 5 Step Process for Success When you engage SPIROL as part of your team we will utilize our 5 Step Process for Success to. Design guidelines for Compression Limiters to avoid the risk of exceeding the elastic limit of the plastic component. The first design is an above-threshold hard-knee compressor with variable ratio thresh-old and gain controls.

Compression limiters are non-threaded inserts that are commonly used in applications where a compressive load is applied to a plastic assembly. For example an ISO 109 grade fastener will require a Compression Limiter made from higher strength materials or a heavier wall cross section than an assembly using an ISO 58 grade fastener. Below or download the Compression Limiters Design Guide.

The block diagram shown in Figure 1 represents a design approach for many end uses including cellular telephone base stations land mobile radios. The Series CL500 Molded-In Compression Limiter is produced with a butted-seam to prevent plastic from entering the inner diameter during the molding process. Compression limiters are non-threaded inserts that are commonly used in applications where a compressive load is applied to a plastic assembly.

Printing to audio is a great way to see how your sound is being processed. SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies. Compression limiters are non-threaded inserts designed to protect plastic parts from loads created by the tightening of bolts.

The compression limiter strengthens the plastic and withstands the compressive force that is applied when a mating screw is tightened in the assembly. The primary function of a Compression Limiter is to provide and. Hole Design Although the split seam Compression Limiters have a broken edge.

Suggestions for alignment are. The integrity of the plastic is not compromised by the load that is applied. 2 Tappex 2019 Brochure.

Ceiling set at -6db and Gain set at 6db resulting in more extreme limiting. Threaded Insert Installation. This controls the volume of input going into the limiter.

Included are the specifications for their standard split seam molded-in and solid wall designs as.

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fastener Fixing Magazine

Advanex Europe Insert Collar Compression Limiters

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly 2015 11 04 Assembly Magazine Assembly

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fluid Power Journal

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

Spirol Industries Spirol Offers Guide To Compression Limiters

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

0 comments

Post a Comment